CAILLAU suggests a large range of manual, pneumatic and electrical tools for assembling CLIC clamps.

Most of these tools have a specific closing distance (distance between jaws in closed state), which fits with the CLIC family.

It is important to use CLIC pliers with the proper closing distance for the assembled CLIC clamps in order to ensure satisfying clamp assemblies. This closing distance must also be checked from time to time during the tool lifecycle as explained in CAILLAU technical instruction sheets for these CLIC fitting tools.

I. Manual CLIC pliers:

CAILLAU part number 540000201:

- Most basic manual assembly pliers for all CLIC clamps except CLIC E and CLIC R96 SP.

- To be used for prototype phase or low volumes projects (less than 50 assembled CLIC clamps per day).

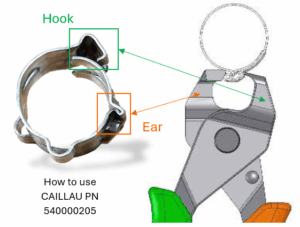

CAILLAU part number 540000205:

-

Standard disassembly pliers for CLIC clamps.

-

To be used for prototype phase, aftermarket or rework operations.

- For disassembling a CLIC clamp with it, the green handler size shall be behind the CLIC clamp hook and the orange handler on the CLIC clamp ear side.

Multiplied pliers:

- Multiplied pliers allow CLIC assembly while requiring less human effort compared to pliers 540000201.

- Handler color indicates the CLIC family (more information in the CLIC fitting tools catalog).

- There is also a multiplied disassembly pliers which can be easily recognized by its red and blue handlers.

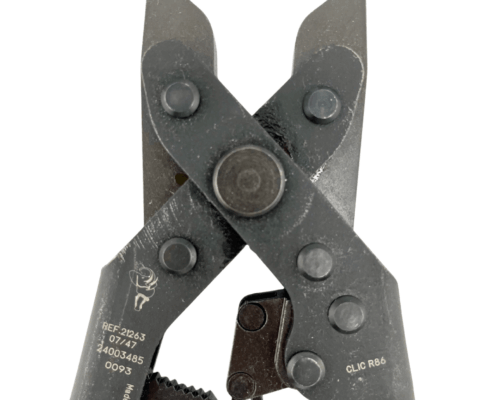

- Anti-return pliers:

- Anti-return pliers do not reopen till it is fully closed. This ensures that the operator presses enough for closing properly the CLIC clamp.

- Pliers jaws can be orientated in the most appropriate way for easing the clamp assembly.

-

Jaws need to be checked on regular basis and changed when they get too worn. To do so, CAILLAU sells spare jaws kit.

-

Please refer to CAILLAU technical instruction sheet V 54 1001 and CLIC fitting tools catalog for more information.

II. Pneumatic CLIC pliers:

- CAILLAU provides pneumatic pliers for assembling CLIC clamps.

- Pliers design depends on the CLIC clamp family.

- Head components such as jaws, axis and springs are sold as spare parts for ensuring the pliers maintenance.

Compact pneumatic pliers:

- Standard pneumatic pliers for closing for assembling large volumes of CLIC clamps.

- Please refer to CAILLAU technical instruction sheet V 54 1006 and CLIC fitting tools catalog for more information.

Calibratable pneumatic pliers:

- Pneumatic pliers for CLIC clamps with assembly control function. CLIC assembly control is performed by following the hook displacement over the ear during the assembly.

- This pliers requires a calibration (learning phase) for teaching the pliers how to recognize an OK clamp assembly.

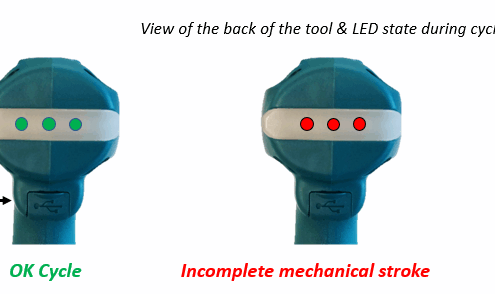

- OK/NOK cycle results are then shared via:

- OK/NOK LED at the back of the pliers

- OK/NOK relay outputs (NC relays)

- Data frames received through RS232 communication

- Please refer to CAILLAU technical instruction sheet V 54 1018 and CLIC fitting tools catalog for more information.

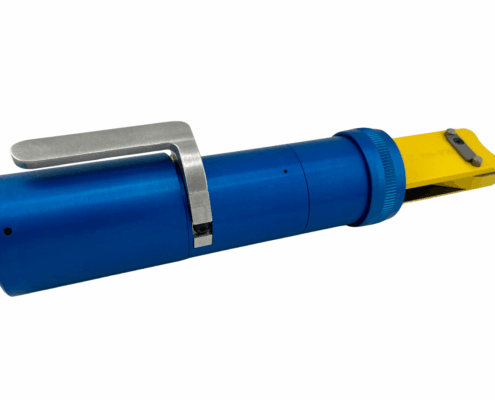

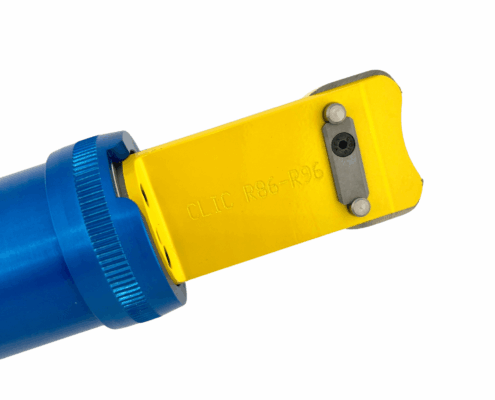

III. Electrical CLIC tool (ECT)

CAILLAU and its official partner BP TECHNOLOGY can provide battery-powered tools for assembling CLIC clamps.

Two versions are available: one equipped with a MAKITA automatic screwdriver and the other with an INGERSOLL RAND automatic screwdriver.

For both versions:

- Pliers design depends on the CLIC clamp family.

- Head components such jaws, axis and springs are sold as spare parts for ensuring the pliers maintenance.

MAKITA ECT:

-

MAKITA ECT version is able to detect an incomplete assembly cycle (jaws not fully closed).

-

OK/NOK assembly cycle results are shared thanks to LED indicator at the back of the tool. In case of a NOK cycle, the tool also releases an audible signal.

- Please refer to CAILLAU technical instruction sheet V 54 1007 for more information.

INGERSOLL RAND ECT:

-

INGERSOLL RAND ECT version is able to check if the assembly cycle is complete (jaws fully closed) and measure a tightening force (torque).

-

INGERSOLL RAND ECT can be sold with a control unit for communicating the OK/NOK assembly results

-

WIFI communication between tool and qcx controller.

-

Possibility of sharing OK/NOK results to a PLC.

-

Assembly cycle results can also be viewed on the control unit display.

-

CLIC fitting tools with tilted heads / jaws:

For some tool versions (manual, pneumatic or electrical), CAILLAU can suggest the use of tilted heads / jaws for being able to close CLIC clamps in assembly environments with limited available space.